Contact us now for a limited-time offer to test your materials free of charge. Don’t miss out—reach out today!

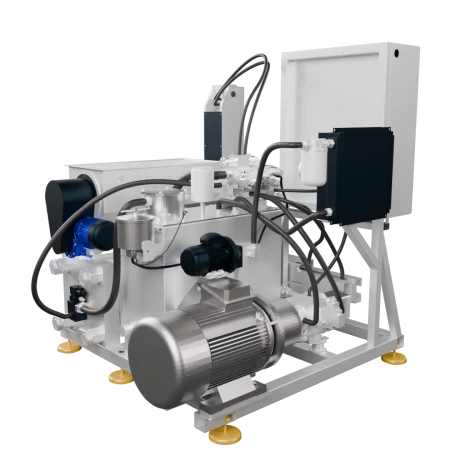

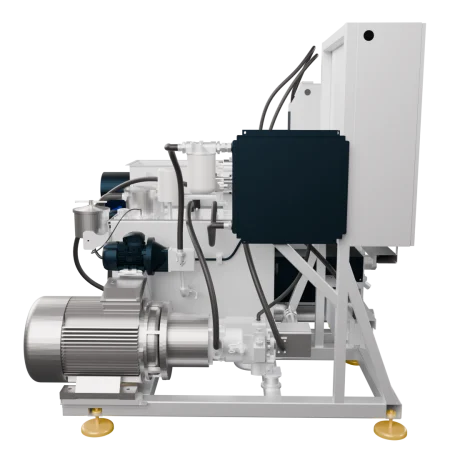

Hydraulic briquetting press BP-500 is a smart investment for wood-working companies, because it is crucial to minimize waste if you want to maximize profits. This is what BP-500 is made for. Briquetting waste from wood sawing or any other wood works. Not only it can briquette wood, but paper, rubber, soft metals, plastic and etc. it is very versatile!

Don’t let valuable byproducts go to waste. Materials like sawdust, biomass, and aluminum swarf—commonly discarded during manufacturing—represent untapped profit potential. By transforming these scraps into high-value briquettes using a hydraulic briquetting press, you can significantly boost their market price.

Our Automated Hydraulic Briquette Press is the perfect solution for this process. Capable of producing up to 600 briquettes per hour, it is designed for continuous 24/7 operation, ensuring maximum efficiency and productivity. The press is versatile and can handle a wide range of materials, including non-ferrous metals, paper, and agricultural byproducts, making it ideal for various industries.

Built to meet all EU standards, our hydraulic briquette press delivers top-quality performance and reliability, helping you optimize your operations while increasing profitability.

Throughput

Main motor

Power

Material Infeed

Sawdust humidity

Max pressure

Oil tank capacity

Lenght

Width

Height

Weight

The BP-500 has a throughput capability of up to 600 briquettes per hour, making it suitable for high-volume production of briquettes from various materials.

Equipped with a 33 kW main motor, the BP-500 ensures powerful operation to drive the hydraulic system and compress materials into briquettes efficiently.

Operates on a standard electrical supply of 380V, 50Hz, providing consistent power to the motor and hydraulic components for continuous operation.

The BP-500 has a length of 1800 mm, providing a compact footprint for installation in various industrial settings while accommodating its operational requirements.

With a width of 1800 mm, the briquette press offers a balanced profile to support efficient material feeding and compression across its operational width.

Stands at a height of 1900 mm, allowing for ergonomic operation and maintenance access while ensuring compatibility with standard ceiling heights in industrial environments.

Weighing 3000 kg, the construction of the BP-500 ensures stability during operation and transportation, contributing to its durability and reliability in industrial applications.

Features a material infeed capacity of 127 liters, allowing for efficient feeding and compression of raw materials such as sawdust, biomass, or non-ferrous metals.

Designed to handle materials with a maximum sawdust humidity of 15%, ensuring optimal briquette quality and production efficiency.

Capable of exerting a maximum pressure of 1700 kg/cm² during the briquetting process, ensuring dense and compact briquette formation suitable for storage and transportation.

Includes a large oil tank with a capacity of 260 liters, ensuring sufficient hydraulic fluid supply to maintain consistent operation and pressure during production.

Throughput

Main motor

Power

Material Infeed

Sawdust humidity

Max pressure

Oil tank capacity

Lenght

Width

Height

Weight

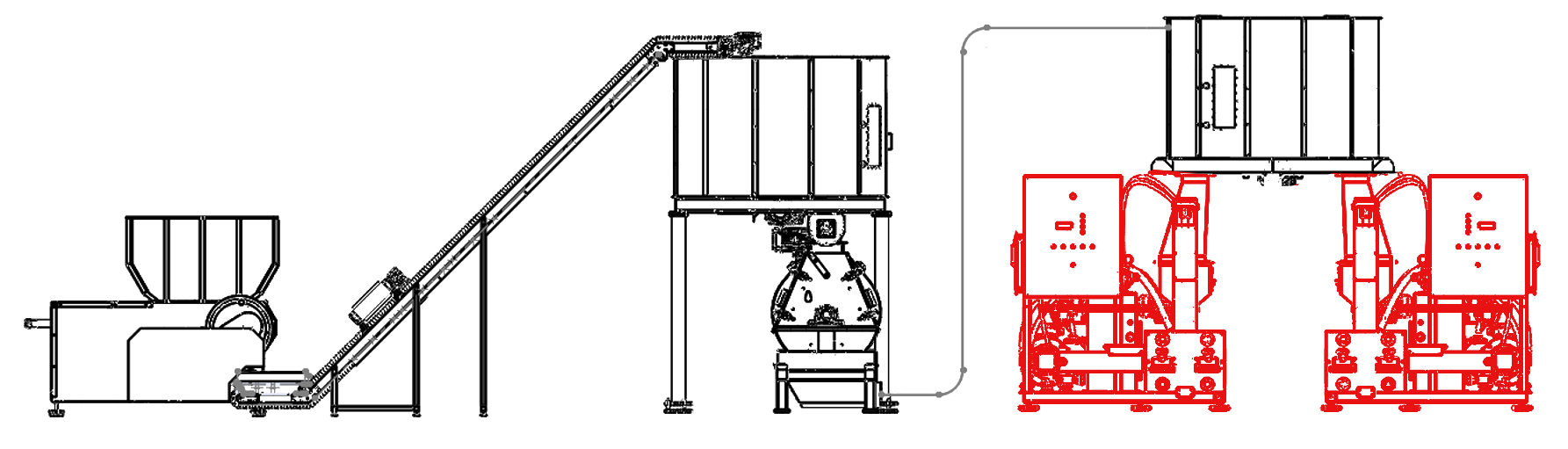

PLACEMENT

SIMILAR

Engineering and manufacturing solutions for the recycling industry.

Deltuvos st. 22 LT-20122 Ukmergė, Lithuania

Copyright © 2024 UMP TECHNIKA | All Rights Reserved | Terms & Conditions | Privacy Policy

CONTACT

Industrial shredders are the perfect waste management solution for any business with an excess of scrap materials to reuse or dispose of.