Contact us now for a limited-time offer to test your materials free of charge. Don’t miss out—reach out today!

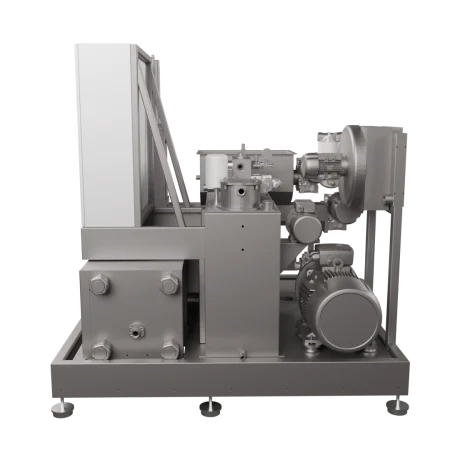

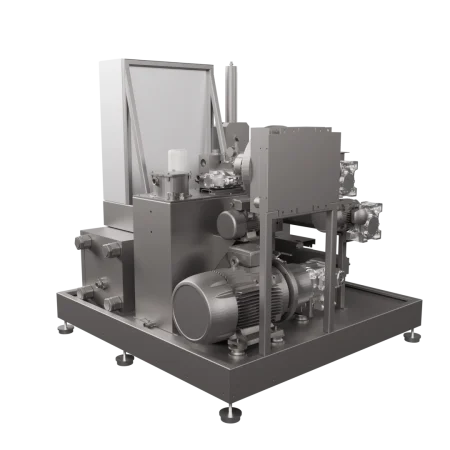

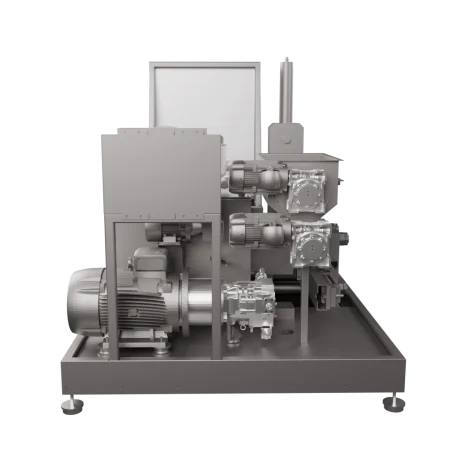

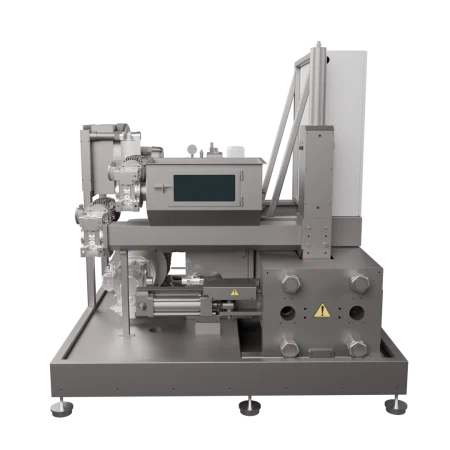

Specialised press built from the ground up for briquetting of aluminum, copper and similar alloys. Includes integrated oil collection pads. Does not include packing table – only briquette guides (slides). Comes with see through bunker doors & oil heating elements as standard. Machines are controlled by Siemens KTP-400 touchscreens. 2nd generation available for purchase from February 2024.

Profits should not be wasted. Aluminum, copper, and any other soft metal swarf leftover from the manufacturing process is usually discarded as is – this means a loss of potential profits. Turning your scraps to briquettes using a briquetter is one of the best ways to increase their price. This is where our automated Hydraulic Briquette Press ALU comes in. It produces up to 600 briquettes per hour and can tackle non-stop operation 24/7. Our equipment could be also used for pressing non-ferrous metal, paper or any secondary product of the farming industry. Hydraulic Briquette Press ALU meets all the requirements of the EU standarts.

Throughput

Main motor

Power

Material Infeed

Sawdust humidity

Max pressure

Oil tank capacity

Lenght

Width

Height

Weight

The ALU can produce up to 600 briquettes per hour, indicating its efficiency in converting raw materials into compact briquettes suitable for various applications.

The ALU is powered by a 33 kW main motor, ensuring robust performance to drive the hydraulic system and compress materials effectively into dense briquettes.

The ALU operates on a standard electrical supply of 380V, 50Hz, providing stable power to the motor and hydraulic components for continuous and reliable operation.

The ALU measures 2000 mm in length, providing a compact footprint suitable for installation in various industrial settings while accommodating its operational requirements.

With a width of 2000 mm, the briquette press offers a balanced profile to support efficient material feeding and compression across its operational width.

The ALU stands at a height of 2200 mm, designed for ergonomic operation and maintenance access while ensuring compatibility with standard industrial space constraints.

Weighing 3500 kg, the sturdy construction of the ALU enhances stability during operation and transportation, ensuring durability and reliability in industrial applications.

Features a material infeed capacity of 127 liters, facilitating efficient feeding and compression of materials such as sawdust, biomass, or other industrial residues.

The humidity does not matter when briquetting metal.

–

Equipped with a large oil tank with a capacity of 260 liters, ensuring ample hydraulic fluid supply to maintain consistent operation and pressure during production.

Throughput

Main motor

Power

Material Infeed

Sawdust humidity

Max pressure

Oil tank capacity

Lenght

Width

Height

Weight

PLACEMENT

SIMILAR

Engineering and manufacturing solutions for the recycling industry.

Deltuvos st. 22 LT-20122 Ukmergė, Lithuania

Copyright © 2024 UMP TECHNIKA | All Rights Reserved | Terms & Conditions | Privacy Policy

CONTACT

Industrial shredders are the perfect waste management solution for any business with an excess of scrap materials to reuse or dispose of.