Contact us now for a limited-time offer to test your materials free of charge. Don’t miss out—reach out today!

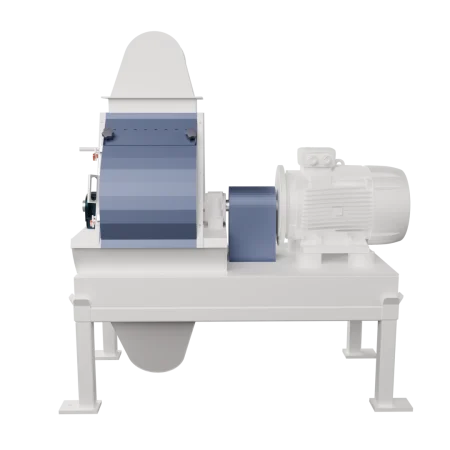

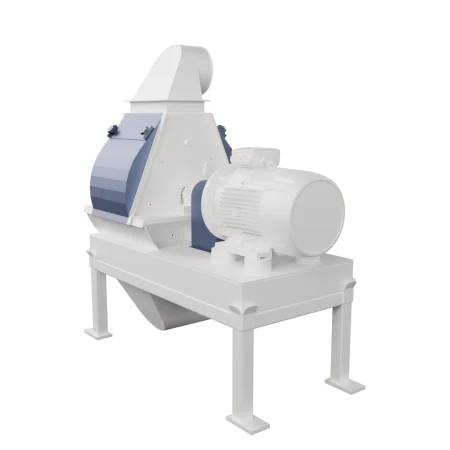

Wood chips are a common by-product generated by woodworking companies during the manufacturing process. Due to low options for realization wood chips are usually discarded by selling it to heating plants for a low price. Our MM-2000 hammer mill allows companies to turn wood chips into briquettable sawdust by shredding and crushing it through metal screens also known as sieves.

Quick-release hatches allow quick and easy access for maintenance while keeping workers safe. Blades of the machine are not fixed and spin freely due to the centrifugal principle. This means that blades take less damage on impact and have an extended lifetime. Fixed blades can be ordered if required for specific produce. The mill can be ordered to fit various produce and applications ranging from reducing biomass waste to spice production, chemical and mineral. The perforated sieves and blades are easily interchangeable to adjust for different types of materials and purposes.

Throughput

Main motor

Revolutions

Blades

Power

Output screen

Lenght

Width

Height

Weight

The MM-2000 hammer mill can process up to 2500 kg/h (kilograms per hour) of material, making it efficient for converting wood chips into briquettable sawdust quickly and effectively.

Equipped with a main motor rated at 37/45/55 kW, the hammer mill provides power to drive the shredding and crushing mechanism, ensuring efficient processing of materials.

Operating at 3000 RPM (revolutions per minute), the mill’s high-speed rotation facilitates rapid shredding and crushing of wood chips, optimizing throughput and productivity.

The hammer mill features 48 units of blades. These blades operate on the centrifugal principle, spinning freely to reduce damage on impact and extend their lifespan, enhancing operational efficiency and durability.

Powered by a standard 380V, 50Hz electrical supply, the mill is compatible with typical industrial power systems, ensuring stable and reliable operation.

Output sieves (screens) ranging from D5 to D10 size specifications. These screens are interchangeable, allowing adjustment for different material types and processing requirements, ensuring versatility in output particle size.

The mill has a length of 1850 mm, providing a compact footprint suitable for integration into existing production lines or workshop environments, optimizing space utilization.

With a width of 900 mm, the mill offers a balanced size that accommodates efficient material feeding and operational accessibility within industrial settings.

Standing at 1650 mm tall, the mill’s height supports ergonomic access for maintenance and operation, while ensuring compatibility with overhead clearance requirements in various industrial settings.

Weighing 1100 kg, the hammer mill strikes a balance between powerful and steady work and ease of installation, relocation, and stability during operation.

Throughput

Main motor

Revolutions

Blades

Power

Output screen

Lenght

Width

Height

Weight

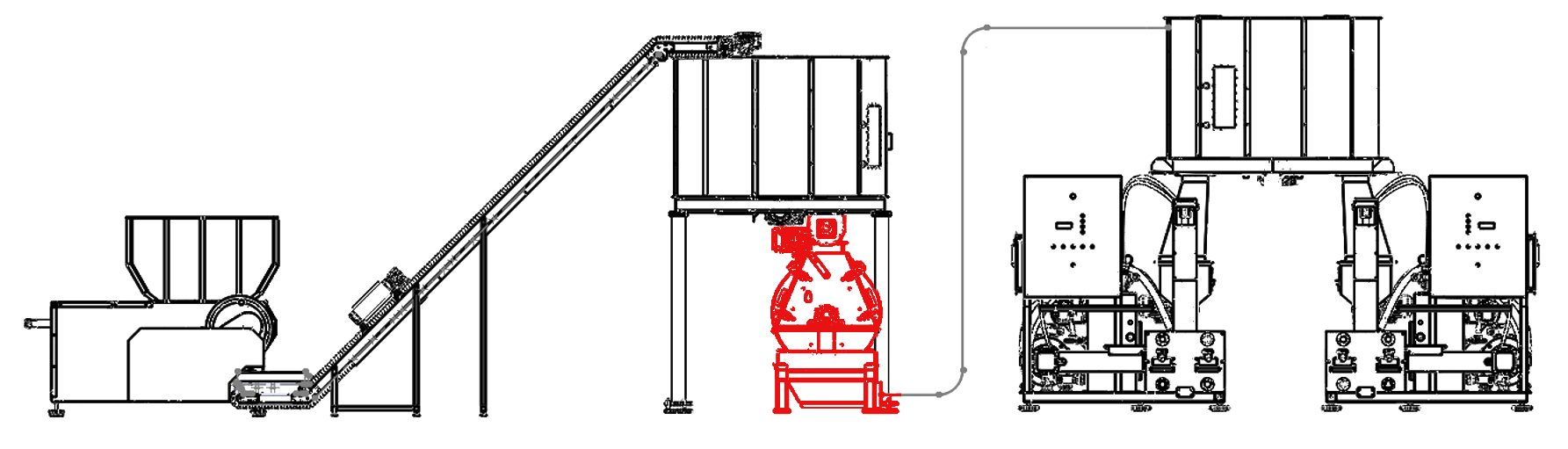

PLACEMENT

SIMILAR

Engineering and manufacturing solutions for the recycling industry.

Deltuvos st. 22 LT-20122 Ukmergė, Lithuania

Copyright © 2024 UMP TECHNIKA | All Rights Reserved | Terms & Conditions | Privacy Policy

CONTACT

Industrial shredders are the perfect waste management solution for any business with an excess of scrap materials to reuse or dispose of.