Contact us now for a limited-time offer to test your materials free of charge. Don’t miss out—reach out today!

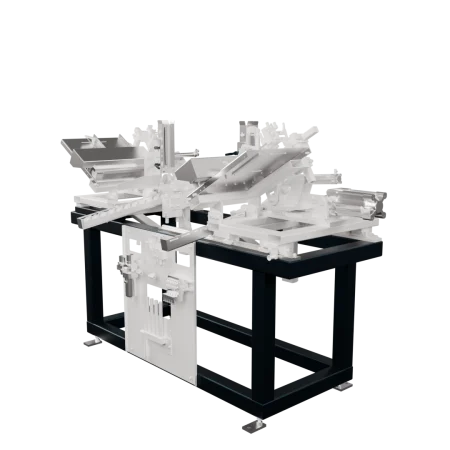

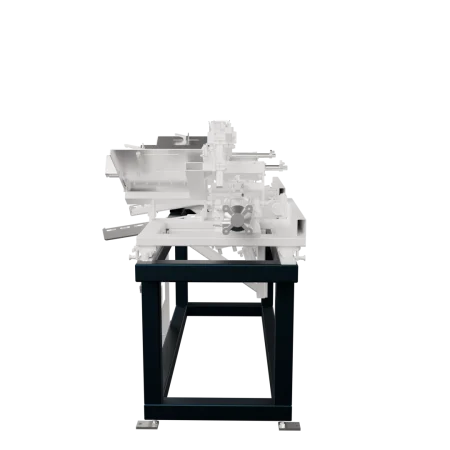

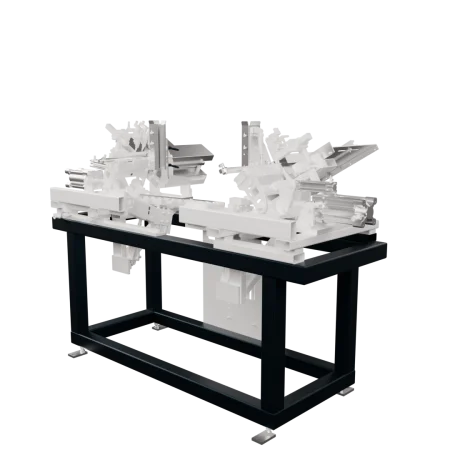

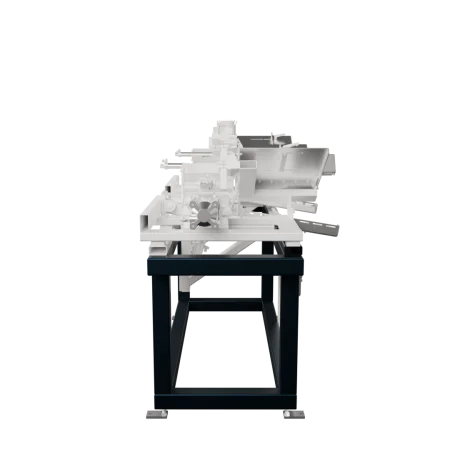

A task was provided to UMP Technika by a client to build a non-standard furniture assembly table which would be fitting to the highest standards of IKEA. The machine has to create a single, end-customer-friendly part out of several different pre-manufactured objects by glueing and pressing them together. The highest assembly quality standards had to be met, as every part built will be tested to make sure that each piece of the furniture will serve well in the houses of end customers. IKEA standards of quality can only be met if the perfect amount of glue is dozed every time and every single press is done with the same force. Painted finishes of the parts had to be preserved during the pressing to pass the quality inspection so no sharp, or abrasive machining finishes were allowed. Ensuring the ergonomics of the machine was another very important feature for maximum manufacturing efficiency.

Your furniture making machinery projects can be made into turn-key solutions delivered to your door. Contact us with your project details to start the discussion about the possible solutions. Made in Lithuania!

SIMILAR

Engineering and manufacturing solutions for the recycling industry.

Deltuvos st. 22 LT-20122 Ukmergė, Lithuania

Copyright © 2024 UMP TECHNIKA | All Rights Reserved | Terms & Conditions | Privacy Policy

CONTACT

Industrial shredders are the perfect waste management solution for any business with an excess of scrap materials to reuse or dispose of.