Contact us now for a limited-time offer to test your materials free of charge. Don’t miss out—reach out today!

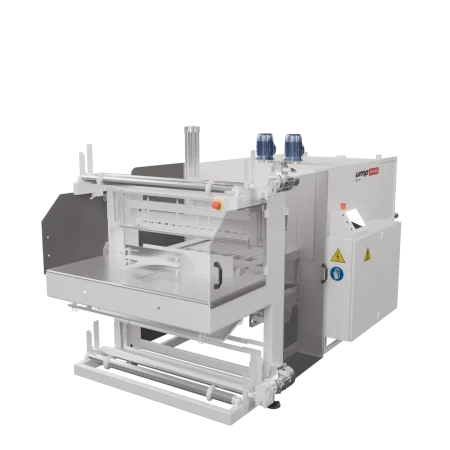

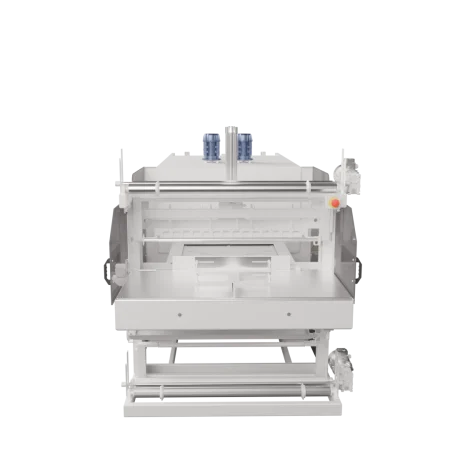

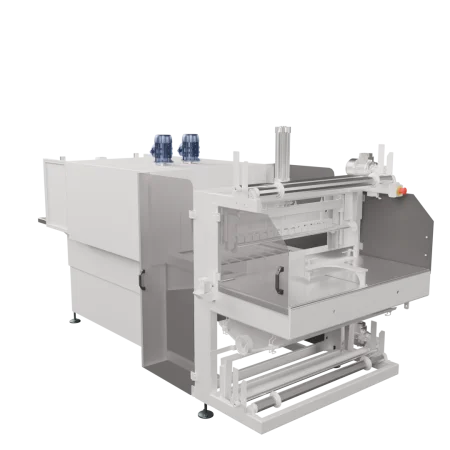

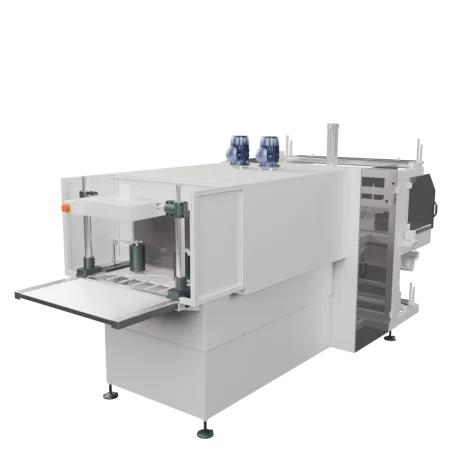

Effortless Briquette Packaging with the Semi-Automated Packing System (SAPS)

Packing briquettes is now faster and more efficient with the Semi-Automated Packing System (SAPS). This advanced system provides a reliable solution for shrink film packaging, ensuring high-quality results for briquettes of all types.

Designed to optimize the packaging process, the SAPS enhances productivity while maintaining the flexibility to meet diverse packaging requirements. Whether you’re packaging wood, biomass, or other materials, the SAPS is a cost-effective and efficient choice for briquette packaging.

Maximize Savings with SAPS: The Ideal Solution for Briquette Packaging

Briquetting is a proven cost-saving solution for companies, and enhancing packing efficiency with the Semi-Automated Packing System (SAPS) further amplifies these benefits.

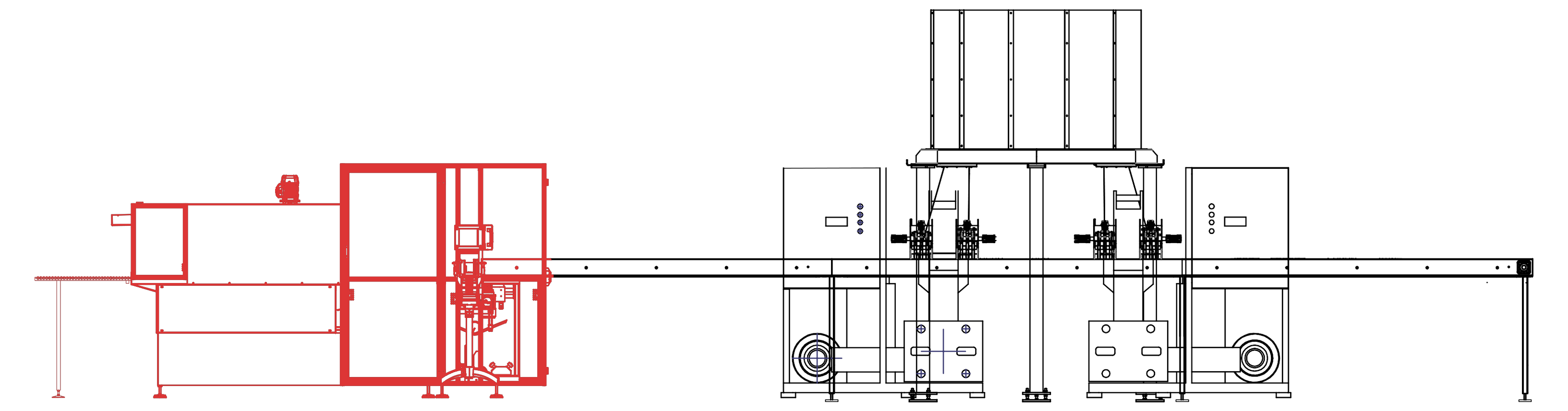

The compact SAPS eliminates the need for an automated transporter system, making it both space-saving and efficient. Its two-sided seam system offers superior dust resistance compared to airless units with long seams. Additionally, a protective plate covers the sealing surface during operation, preventing dust buildup and ensuring consistent sealing quality.

With adjustable package width, the SAPS is highly versatile and can accommodate various products beyond briquettes, such as bottles, sugar packets, and more. For improved ergonomics, it can be equipped with a motorized conveyor that returns packages to the operator, streamlining the workflow.

The SAPS is recommended for use with 1-3 presses, depending on operator capabilities, making it a flexible and efficient solution for businesses aiming to optimize their packaging process.

Throughput

Power

Operation type

Material infeed

Sealing type

Lenght

Width

Height

Weight

The throughput of the SAPS model depends on the operator’s efficiency, highlighting its semi-automatic nature where operator skill and speed play a crucial role in productivity.

The SAPS operates on a power supply of 380V, 50Hz, providing consistent and reliable energy to support its semi-automatic packing operations.

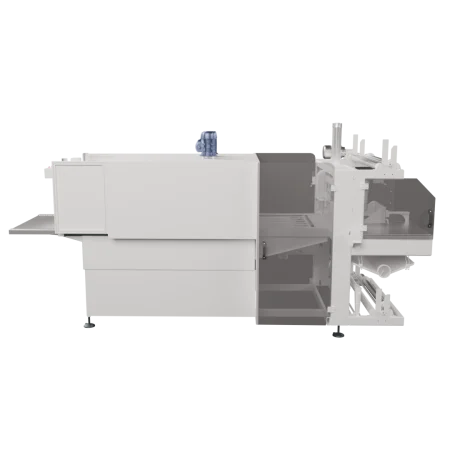

The SAPS measures 3500mm in length, offering a spacious area for manual loading and the subsequent packing process.

With a width of 1500mm, this model maintains a compact profile, making it suitable for various industrial environments while providing adequate space for its semi-automatic functions.

Standing at 2100mm in height, the SAPS model is designed for ergonomic operation and easy access to its manual loading and packing components.

Weighing 700kg, the SAPS is constructed to be robust yet manageable, ensuring stability during operation and ease of installation in different industrial settings.

Material infeed is handled manually, allowing the operator to load materials into the system for further processing and packing.

This model functions as a semi-automatic system, combining manual loading with automated processes to enhance productivity while requiring some level of operator intervention.

Throughput

Power

Operation type

Material infeed

Sealing type

Lenght

Width

Height

Weight

PLACEMENT

SIMILAR

Engineering and manufacturing solutions for the recycling industry.

Deltuvos st. 22 LT-20122 Ukmergė, Lithuania

Copyright © 2024 UMP TECHNIKA | All Rights Reserved | Terms & Conditions | Privacy Policy

CONTACT

Industrial shredders are the perfect waste management solution for any business with an excess of scrap materials to reuse or dispose of.